Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

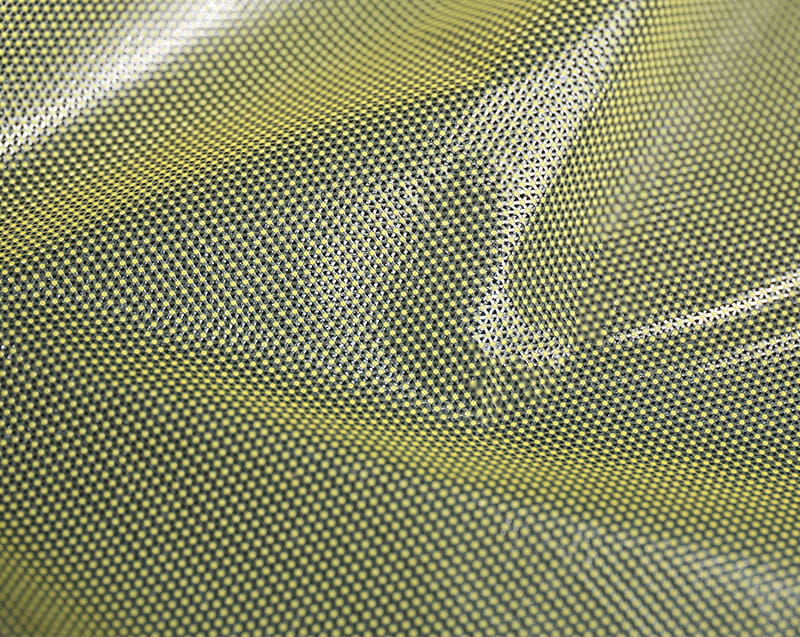

Introduction Hot Melt Adhesive Web is a modern adhesive material that has been widely used in many industrial fields in recent years. Unlike traditional liquid adhesives, hot melt adhesive web has a mesh structure and is mainly made of hot melt adhesive particles through a special process. It can quickly melt and bond after heating. Due to its environmental protection, easy operation, and high bonding strength, hot melt adhesive web has gradually replaced many traditional adhesive products and become the preferred bonding technology in many industries.

Working principle The working principle of Hot Melt Adhesive Web is simple and efficient. The material is solid at room temperature. When heated to a specific temperature, the hot melt adhesive web begins to melt and becomes a viscous liquid substance. When it is applied to the surface of the substrate to be bonded, the melted adhesive layer will quickly penetrate and adhere to the substrate. When the temperature drops, the hot melt adhesive web will re-solidify and form a solid bonding layer. Since the bonding process does not require volatile solvents, the entire operation process is not only environmentally friendly, but also greatly shortens the drying time and improves production efficiency.

Main features

Environmentally friendly: Hot melt adhesive mesh does not contain solvents or harmful chemicals, and does not release volatile organic compounds (VOCs) during heating and use, so it meets the high environmental protection requirements of modern industry.

Quick bonding: Hot melt adhesive mesh can melt and complete bonding in a few seconds, which greatly improves the working efficiency of the production line compared to traditional bonding methods. Especially in occasions where large-scale and rapid production is required, the application effect of hot melt adhesive mesh is particularly significant.

Adjustable: The melting point and viscosity of hot melt adhesive mesh can be adjusted according to different application requirements, and it is very adaptable. This makes it widely used in multiple industries, covering a variety of needs from high temperature tolerance to low temperature bonding.

Industrial applications

Electronic industry: In the electronics industry, hot melt adhesive mesh is often used to bond circuit boards and electronic components. Due to its fast bonding and solvent-free characteristics, it ensures the safe and efficient assembly of electronic components. In addition, hot melt adhesive mesh can also resist heat and vibration in electrical equipment, providing stable long-term protection.

Construction industry: The bonding of building materials often requires high strength and long-term durability. Hot Melt Adhesive Web can effectively bond materials such as wood, metal and plastic, especially in the bonding of door and window frames, wall panels and carpets. Its water resistance and aging resistance enable it to maintain stable bonding effects under different climatic conditions.

Medical supplies: The medical industry has strict non-toxic and high-efficiency requirements for bonding materials. Hot melt adhesive web is particularly important in the bonding of non-woven fabrics, such as the production of disposable masks and medical gauze. Its rapid curing and safety greatly improve production efficiency while ensuring the safe use of medical products.

Furniture manufacturing: In the furniture industry, hot melt adhesive web is often used to bond fabrics to frames, especially in soft furnishings such as sofas and mattresses. Due to its excellent adhesion and traceless characteristics, furniture manufacturers can achieve dual guarantees of product appearance and quality. In addition, the environmental protection and durability of hot melt adhesive web also meet the needs of modern consumers for green home products.

Advantages and future development

Save time and cost: Since hot melt adhesive web can be quickly melted and cured, there is no need to wait for a long time to dry during the production process, which significantly improves the efficiency of industrial production. At the same time, it is easy to operate, reducing the requirements for professional skills, thereby reducing labor costs.

Sustainable development: With the increasing global attention to sustainable development and environmental protection, the environmental friendliness of hot melt adhesive mesh gives it great development potential in the future. There is no solvent volatilization and no harmful substance residue during the production process, which fully meets the requirements of green production. In addition, with the continuous advancement of material technology, the performance of hot melt adhesive mesh is expected to be further improved in the future to meet the needs of more industries.