Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

In the world of materials science, innovation often comes in unassuming forms. One such breakthrough is the elastic reticular film sheet—a material that has quietly revolutionized industries ranging from healthcare to packaging. Combining flexibility, strength, and adaptability, this unique material offers a host of possibilities for modern applications. But what exactly is an elastic reticular film sheet, and why is it gaining so much attention?

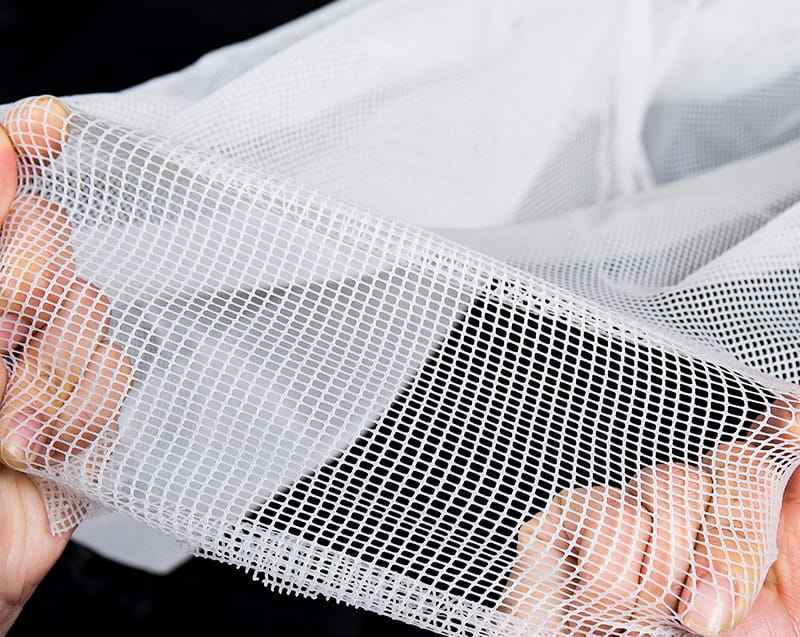

At its core, an elastic reticular film sheet is a thin, flexible material characterized by a lattice-like or netted structure. This "reticulated" design gives the sheet its defining properties: elasticity, breathability, and resilience. The open structure allows air and moisture to pass through while maintaining structural integrity, making it ideal for applications where traditional solid films might fall short. Whether stretched, compressed, or twisted, these sheets retain their shape and functionality, showcasing remarkable durability.

One of the most prominent uses of elastic reticular film sheets is in the medical field. Their breathable yet durable nature makes them perfect for wound care products like bandages and dressings. Unlike conventional materials, which can trap moisture and delay healing, these sheets allow the skin to breathe while protecting against contaminants. Additionally, their elasticity ensures a snug fit, even on curved or irregular body parts, enhancing patient comfort and promoting faster recovery.

Beyond healthcare, the versatility of elastic reticular film sheets extends into the realm of fashion and textiles. Designers are increasingly incorporating these materials into sportswear and activewear due to their ability to stretch without losing form. The open structure also enhances airflow, keeping wearers cool and comfortable during intense physical activity. Moreover, their lightweight nature makes them an attractive option for creating garments that prioritize both performance and aesthetics.

In the packaging industry, elastic reticular film sheets are proving to be a game-changer. Traditional plastic wraps, while effective, often lack the adaptability needed for irregularly shaped items. These sheets, on the other hand, can conform to virtually any shape, providing secure coverage without excess material. This not only reduces waste but also improves efficiency in logistics and storage. Furthermore, their recyclable nature aligns with the growing demand for sustainable packaging solutions.

Another fascinating application lies in filtration systems. The porous structure of elastic reticular film sheets makes them excellent candidates for air and liquid filtration. By allowing fluids to pass through while capturing impurities, they offer a cost-effective and efficient way to purify water or improve indoor air quality. Their elasticity also means they can withstand pressure changes without compromising performance, ensuring consistent results over time.

What sets elastic reticular film sheets apart is their potential for customization. Manufacturers can tweak variables such as pore size, thickness, and material composition to tailor the sheets for specific needs. For instance, a finer mesh might be used for high-precision filtration, while a coarser structure could work better for ventilation purposes. This adaptability opens up new avenues for research and development, pushing the boundaries of what these sheets can achieve.

As technology continues to advance, the role of elastic reticular film sheets is likely to expand even further. Researchers are exploring ways to integrate smart technologies, such as sensors or conductive elements, into the material itself. Imagine a bandage that monitors wound healing in real-time or athletic gear that tracks muscle movement—these futuristic ideas are becoming increasingly plausible thanks to innovations in material science.