Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

What Makes Elastic Non-Woven Fabric Unique?

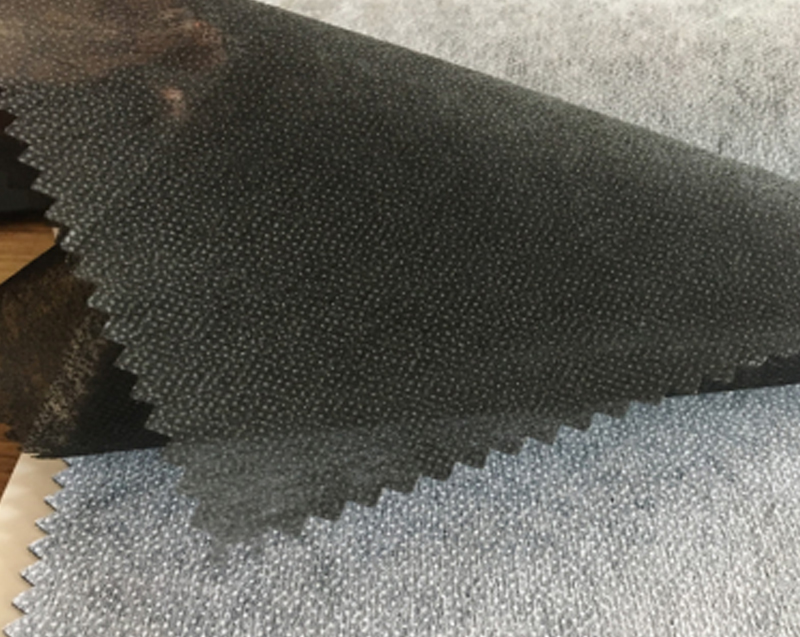

Unlike woven fabrics, which are made by interlacing yarns in a structured pattern, non-woven fabrics are produced by bonding fibers together without any traditional weaving or knitting. These fibers can be bonded using heat, chemicals, or mechanical pressure, creating a durable, strong fabric that is lightweight and breathable.

Elastic non-woven fabric takes this a step further by incorporating elastic fibers, typically spandex or elastane, into the mix. These fibers allow the fabric to stretch and return to its original shape, providing superior flexibility and comfort. The addition of elasticity makes the fabric suitable for applications where stretchability and resilience are essential.

Key Benefits of Elastic Non-Woven Fabric

Elastic non-woven fabric offers a range of benefits that make it ideal for a wide array of uses. Some of the most important advantages include:

Flexibility and Comfort: Elastic fibers ensure that the fabric can stretch to accommodate the shape and movements of the body, which is particularly important in activewear, medical garments, and hygiene products.

Improved Durability: Elastic non-woven fabrics are strong and resilient, making them suitable for both short-term disposable products and long-lasting applications.

Breathability: Non-woven fabrics, by nature, allow air to pass through, which helps regulate temperature and moisture, making them comfortable for extended wear.

Lightweight: The fabric retains the lightweight properties of traditional non-woven materials, making it easy to wear and handle without feeling heavy or cumbersome.

Cost-Effective: Elastic non-woven fabrics are generally cost-effective to produce, making them a popular choice for manufacturers who need a balance of performance and affordability.

Industries That Benefit from Elastic Non-Woven Fabric

Elastic non-woven fabric’s unique properties have made it a preferred choice in several industries. Below are some key sectors where this fabric is making an impact:

1. Healthcare and Medical

In healthcare, elastic non-woven fabric is commonly used in medical garments such as surgical gowns, face masks, and protective clothing. The fabric’s ability to stretch allows for a snug fit while maintaining breathability and comfort, which is vital in medical settings. It is also used in disposable items like diapers and feminine hygiene products, where both flexibility and absorbency are important.

2. Fashion and Apparel

The fashion industry uses elastic non-woven fabric to create comfortable, form-fitting garments such as leggings, activewear, and undergarments. Its stretchability ensures that the fabric moves with the body, providing comfort and freedom of movement. Additionally, the softness and breathability make it an ideal fabric for underclothing and sleepwear.

3. Packaging and Consumer Goods

Elastic non-woven fabric is also used in packaging applications. Its flexibility and durability make it perfect for wrapping delicate products, such as electronics or cosmetics, offering both protection and an attractive presentation. Its lightweight nature helps reduce shipping costs, making it a sustainable choice for packaging companies.

4. Home Textiles

From upholstery to mattress covers, elastic non-woven fabric is widely used in the home textiles industry. Its stretch allows it to fit snugly around furniture or mattresses, ensuring a neat and tidy appearance while offering comfort. The fabric is also used in dust covers and storage bags, where breathability is crucial for keeping items fresh.

5. Automotive

In the automotive industry, elastic non-woven fabric is used for interior applications, such as seat covers and headliners. The stretchable nature of the fabric ensures a snug, smooth fit, enhancing the overall comfort and aesthetic appeal of vehicle interiors. It also contributes to the reduction of noise and heat, making it a multifunctional material in automotive design.