Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

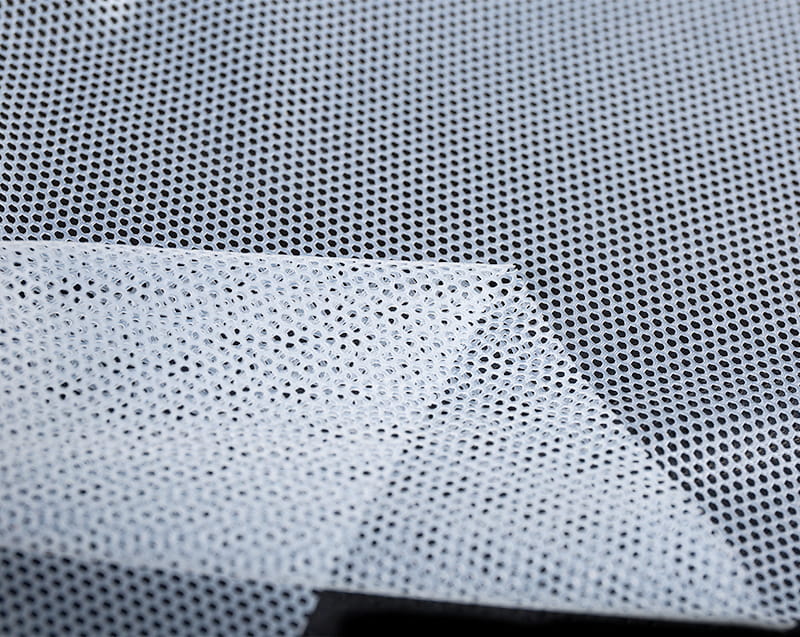

Hot melt bonding net film has become an indispensable material in various industries due to its excellent bonding properties and ease of application. This film is made of specialized thermoplastic materials that melt under heat and bond to substrates when applied, creating a strong, reliable bond without the need for additional adhesives or solvents. As its name suggests, it relies on heat to activate its bonding ability, offering an efficient, clean, and eco-friendly alternative to traditional adhesive methods.

The technology behind hot melt bonding net film is relatively simple yet highly effective. The film is typically made from a blend of polyethylene, polyurethane, or other synthetic resins, depending on the desired properties. Once heated, the film melts and forms a solid bond as it cools, providing a tight and durable connection between different surfaces. This process does not require any additional curing time or complex machinery, which significantly reduces production times and costs.

One of the key advantages of hot melt bonding net film is its versatility. It is used in a wide range of industries, including automotive, textiles, electronics, packaging, and construction. In the automotive industry, for example, the film is used to bond components like insulation materials, fabrics, and trims to the interior and exterior of vehicles. The automotive sector appreciates the film's ability to create strong, vibration-resistant bonds that are not affected by temperature fluctuations, which is crucial for the demanding environments vehicles endure.

In the textile industry, hot melt bonding net film is commonly used for bonding fabrics together, particularly in nonwoven fabric production. The film can be applied to a variety of textile materials, including polyester, nylon, and cotton, creating strong, durable seams without the need for sewing or other traditional methods. This capability allows manufacturers to streamline production processes and create high-quality products more efficiently. Additionally, the bonding net film is often used in the production of activewear, sportswear, and outdoor gear, where durability, flexibility, and resistance to extreme conditions are paramount.

The packaging industry has also embraced hot melt bonding net film, particularly in the production of flexible packaging materials. The film can be used to seal packaging for food, pharmaceuticals, and consumer goods, ensuring airtight, tamper-proof seals that enhance product shelf life and safety. Hot melt bonding is preferred in this sector because it creates a clean and reliable bond without the need for additional chemicals, making it a safe choice for packaging food and other sensitive products.

Aside from its practical applications, hot melt bonding net film also offers significant environmental benefits. Unlike traditional solvent-based adhesives, which can release harmful volatile organic compounds (VOCs) into the environment, hot melt bonding net film is typically free of such substances. This makes it a more environmentally friendly choice, particularly in industries where sustainability is a key concern. Additionally, the film is highly efficient in terms of energy consumption, as it requires less heat and curing time compared to other bonding methods.

Another notable benefit of hot melt bonding net film is its cost-effectiveness. The simplicity of the bonding process, combined with the reduction in labor and material costs, makes it an attractive option for manufacturers seeking to improve their bottom line. Furthermore, the film’s ability to bond quickly and reliably means that production lines can operate at higher speeds, reducing overall production costs.