Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

In the fast-paced world of manufacturing, efficiency, cost-effectiveness, and environmental sustainability are more important than ever. Hot melt bonding net film is one material that has gained significant attention in recent years due to its ability to address all these concerns and more. This thermoplastic bonding solution is transforming various industries by providing a fast, clean, and effective way to bond materials without the need for solvents, additional adhesives, or complex machinery.

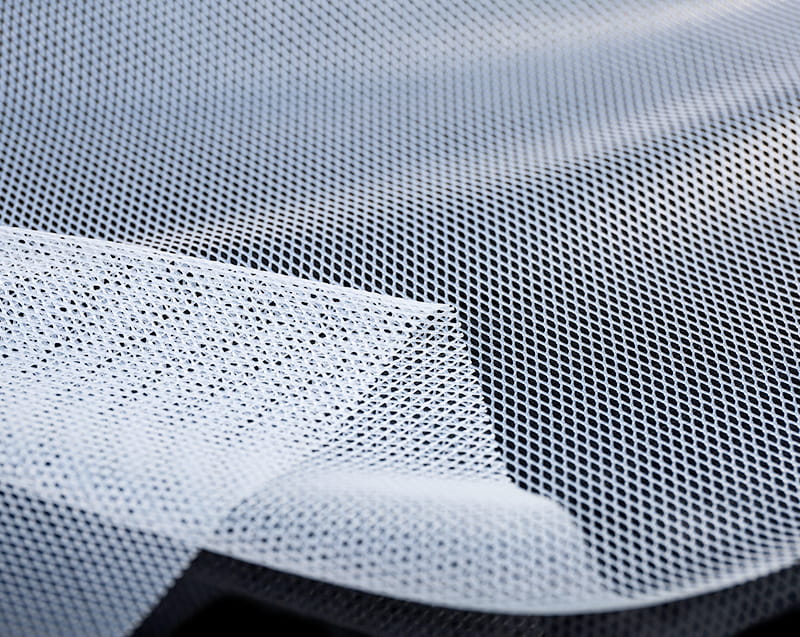

At its core, hot melt bonding net film consists of a thin layer of thermoplastic material that melts when heated and solidifies as it cools, creating a strong bond between substrates. Unlike traditional adhesives, which often require mixing, curing, or the use of solvents, hot melt bonding film simplifies the process. The material is already in a ready-to-use form, and its bonding properties are activated solely by heat, making it a time-efficient option for manufacturers.

The automotive industry is one of the key sectors benefiting from this innovative bonding solution. In vehicles, hot melt bonding net film is used to secure insulation materials, interior trim components, and fabric linings. Traditional bonding methods, such as adhesives or stitching, can be time-consuming and costly, but hot melt bonding offers a faster, more reliable alternative. It also helps reduce the weight of vehicles by eliminating the need for heavy adhesives or stitching, contributing to fuel efficiency and performance. Additionally, the bonds created by hot melt bonding are highly resistant to vibration, temperature changes, and moisture, ensuring that the materials remain intact under extreme conditions.

Another industry experiencing the transformative power of hot melt bonding net film is textiles. Manufacturers of nonwoven fabrics, such as those used in medical supplies, hygiene products, and home textiles, are increasingly adopting this bonding technique. Hot melt bonding net film offers a seamless, strong bond between different fabric layers without the need for needle and thread, reducing labor costs and production time. The result is a clean, durable product that can withstand wear and tear while maintaining its comfort and flexibility. Furthermore, hot melt bonding films are often chosen for their ability to bond a wide range of materials, such as cotton, polyester, and synthetic fabrics, making them highly versatile.

The packaging industry has also made great strides by incorporating hot melt bonding net film into their production processes. For instance, flexible packaging solutions for food, beverages, and pharmaceuticals rely on hot melt bonding for airtight seals. This technology is particularly advantageous in food packaging, as it ensures a strong seal without the need for chemicals that could potentially contaminate the product. The fast bonding process also improves efficiency on production lines, allowing manufacturers to produce more units in less time while maintaining high product quality.

Hot melt bonding net film is not only transforming traditional industries, but it’s also playing a pivotal role in advancing sustainability. Traditional adhesives can be harmful to the environment, releasing volatile organic compounds (VOCs) that contribute to air pollution and other environmental issues. Hot melt bonding, on the other hand, is a cleaner process, with minimal emissions and no need for harmful chemicals. This eco-friendly approach is especially important as manufacturers face increasing pressure to adopt sustainable practices and reduce their carbon footprint.