Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

The Manufacturing Process

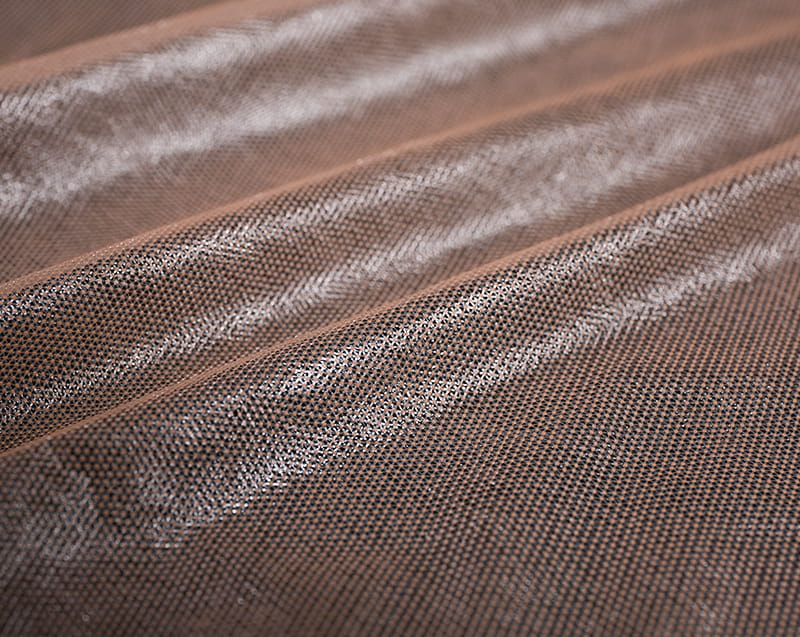

The production of HDPE Apertured Film starts with the creation of a thin sheet of HDPE. HDPE itself is a highly durable material that exhibits superior tensile strength, excellent chemical resistance, and long-lasting durability. The plastic is first extruded into thin sheets, which are then subjected to a perforation process.

The perforation process involves using specialized equipment that creates a pattern of holes or apertures in the film. The size, shape, and density of the apertures can be customized according to the specific needs of the application. These perforations enable the film to perform various functions, such as allowing air or liquid to pass through, while still maintaining the film’s strength and resistance to external stresses.

Key Benefits of HDPE Apertured Film

Enhanced Airflow and Breathability

The perforations in HDPE Apertured Film allow air to flow freely through the material. This characteristic makes it ideal for applications where breathability is essential. For example, in the agricultural sector, the film can be used for greenhouse covers, allowing plants to receive adequate light and air circulation without the risk of heat buildup. Similarly, in packaging, the film helps to maintain freshness by providing ventilation, which is crucial for storing perishable goods.

Improved Filtration Efficiency

HDPE Apertured Film is an excellent material for filtration systems. Its unique perforated design allows for the effective removal of unwanted particles or contaminants while allowing air, water, or other fluids to pass through. The material is widely used in water filtration applications, where it serves as a filter medium to trap debris while allowing clean water to flow through.

Cost-Effectiveness

In the manufacturing world, cost savings are always a priority. HDPE Apertured Film provides an economical solution to a variety of needs. The material is not only affordable to produce but also offers a longer lifespan than other materials. Its durability and resistance to wear and tear reduce the need for frequent replacements, making it a cost-effective option in the long run.

Customization Options

One of the most significant advantages of HDPE Apertured Film is its versatility. Manufacturers can customize the size, shape, and density of the apertures to meet specific needs. Whether the application requires a fine mesh or larger perforations, HDPE Apertured Film can be adapted to suit a wide range of functions. This customization also makes it suitable for use in different industries, from agriculture and packaging to automotive and medical sectors.

Durability and Strength

HDPE itself is a material known for its strength. When combined with perforations, HDPE Apertured Film retains much of the strength and resilience of the original plastic. The film can withstand harsh environmental conditions, including exposure to UV radiation, chemicals, and physical stress. This durability makes it suitable for both indoor and outdoor applications, ensuring it performs well over extended periods.

Applications in Modern Manufacturing

HDPE Apertured Film is used across a variety of industries, each of which benefits from the film's unique properties. Some of the most common applications include:

Agricultural Films: Used for greenhouse covers, tunnels, and crop protection, where the film’s breathable nature and light diffusion properties enhance growing conditions.

Packaging: Often used for products that require ventilation, such as food packaging and fresh produce bags, where it helps preserve the freshness of the products.

Water Filtration: Used as part of filtration systems, such as water treatment plants, to trap impurities while allowing clean water to flow through.

Medical Filtration: Utilized in medical devices and filtration products, such as air and water filters, where its perforated structure provides efficient filtration without compromising on strength.