Welcome to Pinghu Zhanpeng Hot Melt Adhesive Web & Film Co., Ltd. Enterprise Official Website.

1. Medical Industry

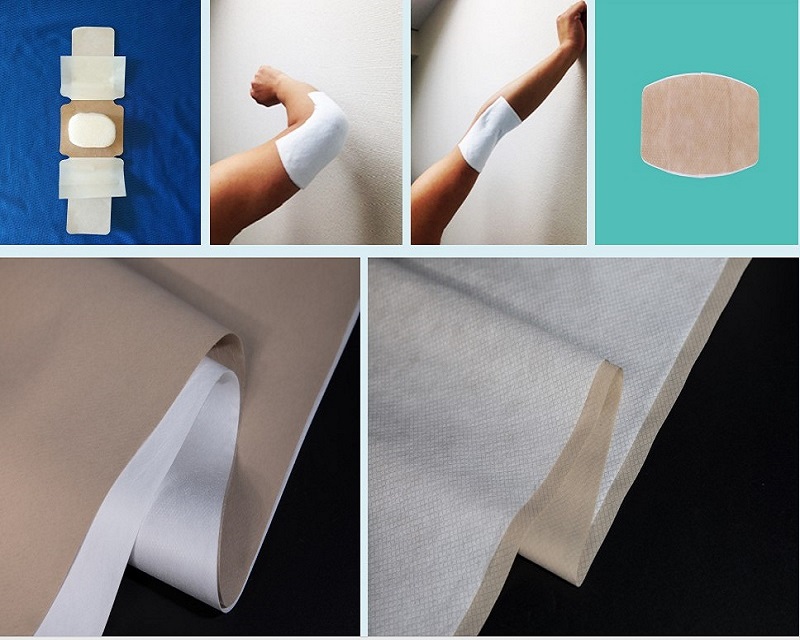

One of the most significant applications of elastic non-woven fabric is in the medical field. The fabric’s breathable, lightweight, and stretchable nature makes it an ideal choice for creating personal protective equipment (PPE), such as surgical gowns, masks, and wound care products. The fabric’s elasticity ensures a snug fit without compromising comfort, which is especially important for medical staff who need to move freely while maintaining protection.

Elastic non-woven fabric is also used in wound dressings and diapers, where its absorbent and soft properties ensure that the patient’s skin remains dry and protected from external contaminants. Additionally, its hypoallergenic nature makes it a safe choice for medical uses, ensuring minimal risk of irritation.

2. Fashion and Apparel

The fashion industry has embraced elastic non-woven fabric for its ability to mold and conform to body shapes. From activewear to undergarments, this fabric offers comfort and flexibility that traditional woven fabrics cannot match. The elasticity of the fabric allows for designs that require less stitching and fewer seams, reducing production time and cost.

Elastic non-woven fabric is also gaining popularity in footwear manufacturing. It’s used in the production of shoes, particularly in parts like the shoe uppers or inner linings, where stretch and comfort are vital. The lightweight yet durable nature of this fabric ensures that the shoes remain both breathable and long-lasting.

3. Automotive Industry

In automotive applications, elastic non-woven fabric is often used in the production of car seat covers, headliners, and soundproofing materials. The fabric’s stretchability allows it to fit various contours, which is crucial for ensuring that car interiors are both aesthetically pleasing and functional. Its moisture-wicking properties also contribute to maintaining comfort during long drives, helping drivers and passengers stay cool and dry.

Additionally, non-woven fabric plays an essential role in the manufacturing of air filters and insulation materials for vehicles. By combining elasticity with superior filtration capabilities, it helps improve air quality inside vehicles and contributes to sound dampening.

4. Packaging Solutions

Elastic non-woven fabric has found its place in the packaging sector, particularly for products that require protection during storage and transport. Whether it's for fragile items, electronics, or even food packaging, elastic non-woven fabrics can be used as cushioning materials. Their stretchability helps them conform to irregularly shaped products, providing a protective barrier while reducing the need for excessive packaging materials.

The fabric is also an eco-friendly alternative to plastic and other non-biodegradable materials, making it an attractive option for sustainable packaging solutions.

5. Home and Household Products

Elastic non-woven fabric is also used in home textiles, including furniture covers, curtains, and bedding products. The fabric's ability to stretch and conform makes it ideal for products that need to fit snugly or adapt to various sizes. Its breathability ensures comfort, while its durability guarantees long-lasting performance in household items.